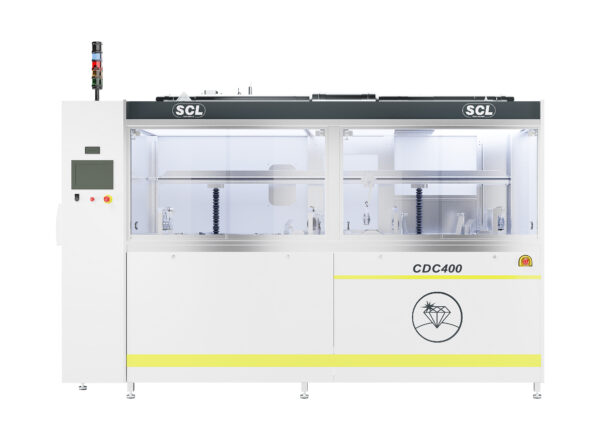

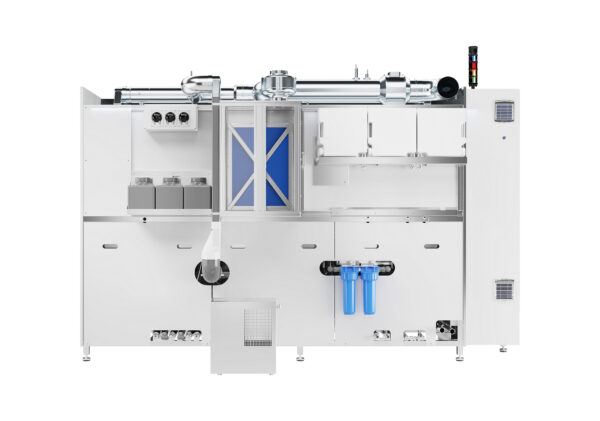

The CDC 400 machine is part of the Compact range. Without compromising quality but with a controlled budget. Producing 60 lenses/h, it is a perfect fit for small to medium size laboratories. A 2-axis robot for the racks manipulation enables to respect the recipes for each type of lenses. The six cleaning tanks enable to clean and prepare the lenses according to their raw material. 1 primer tank and 2 varnishing tanks allow all the varnishing process for all types of lenses. Varnishing takes place by dipping and thermal polymerization. An automatic detergent and alcohol refilling system provides a consistent and stable process control, an easy maintenance and no production stop. A unique water cascading and filtrating system enables to save up to 75%, making the CDC 400 an environmentally-friendly coater.

This machine can be completed with the following items:

- Chillers to maintain the coating temperature +5 → +20°C

- Curring ovens: stand alone or in-line

- Automatic osmosis unit for ultra pure water production

- Draining tank with lift pump

- Ultrasonic stripping for lenses and racks: stand alone or automatic cleaning machine

- A/C unit for coating zone

- Ergonomic preparation/control station

- Lens-holders and rack for 6 lenses