SCL offers a wide range of cleaning equipments dedicated to the opthtalmic industry, with a broad portfolio of machines and processes, fitting to a small or large size production (300 to 2200L/8h).

SCL experience is based on developing and building sophisticated cleaning systems by Ultra sonic, Brushing or High pressure for over 29 years, adapted to a specific cleaning function.

The innovation and a responsive service team make possible to design automatic or semi automatic machines adapted to each customer’s request with competitive prices.

The cleaning process includes removing contaminations like adhesive and polishing liquid residues, fingerprints, and inks marks from parts or lenses. It can also be set to strip hardcoated lenses.

The Ultra sonic cleaning process takes place prior to the coating to prepare lenses ready for inspection.

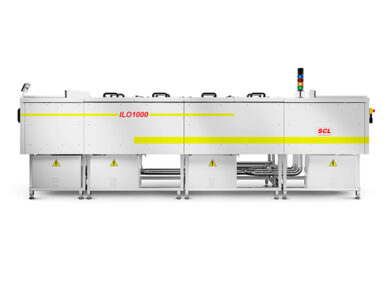

The Brushing or high pressure automated in-line cleaning machines ensure operator free, and full automation processes and produce lenses ready to coat.

Ideal for cleaning lenses after surfacing or finishing process, the brush cleaning systems help to increase yield in downstream coating processes. This way, the laboratory saves time and makes lens production less expensive.

All products