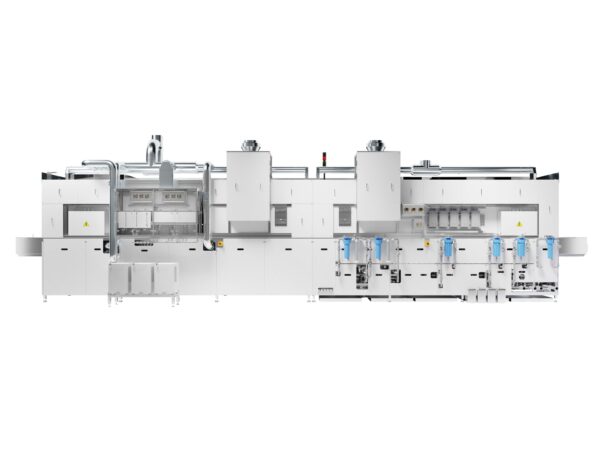

The fully automated high-volume CDS 2000 includes everything you have ever dreamed of : separate zones for cleaning and hard coating, avoiding humidity. It meets all requirements of clean room classifications (ISO 6). Two robots, handling the racks, shorten cycle times, ensuring higher throughput. In- and out- conveyors and buffers contribute to less contamination in the process zones. The hard coater features automatic detergent, alcohol and varnish refilling. Process steps are stable and continuous. It is easy to maintain and a remote connection to SCL ensures fast diagnosis & support. Sustainability and optimized water and energy consumption round off the portfolio of machine benefits.

This machine can be completed with the following items:

- Chillers to maintain the coating temperature +5 → +20°C

- Curring ovens: stand alone or in-line

- Automatic osmosis unit for ultra pure water production

- Draining tank with lift pump

- Ultrasonic stripping for lenses and racks: stand alone or automatic cleaning machine

- A/C unit for coating zone

- Ergonomic preparation/control station

- Lens-holders and rack for 28 or 32 lenses